a trusted brand under the Spinks World Group,

provides a comprehensive range of advanced printing solutions, including pad printing, laser marking, digital printing, and

screen printing. In

pad printing, we use specially formulated silicone pads designed to transfer sharp,

high-resolution images from the cliché to the target surface with precision and clarity. Our

silicone pads are manufactured in India to meet international quality standards and are readily

available on demand to meet diverse industry needs.

a trusted brand under the Spinks World Group,

provides a comprehensive range of advanced printing solutions, including pad printing, laser marking, digital printing, and

screen printing. In

pad printing, we use specially formulated silicone pads designed to transfer sharp,

high-resolution images from the cliché to the target surface with precision and clarity. Our

silicone pads are manufactured in India to meet international quality standards and are readily

available on demand to meet diverse industry needs.

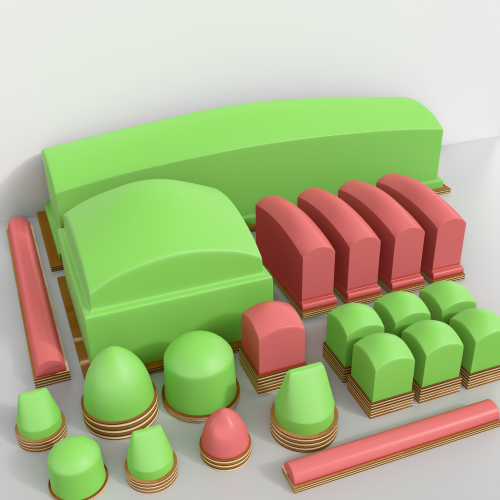

Standard printing pads are used in a pad printing machine to transfer ink from an etched plate (called a cliché) onto a substrate. Standard silicone printing pads are recommended for long-run print jobs with minimal changeovers. ... These are made from silicone rubber material to allow flexibility and ink transfer without absorbing the ink. Standard silicone pads are the best quality printing in the long run and come in various shapes, sizes, and hardnesses to suit different printing needs.

Spinks World offers customized silicone printing pads designed for complex or irregular surfaces. Our special pads can be tailored in shape, size, and hardness to ensure accurate ink transfer from the cliché to 3D objects ... We offer a pad of every shape that is Ideal for curved, textured, or recessed surfaces, they’re used across industries like medical, automotive, electronics, and toys, where precise, high-quality printing is essential. By conforming to challenging surfaces without distorting the printed image, Silicone customized special printing pads help achieve high-quality results with fine details and multi-color designs.

The number of our silicone printing pads is made to transfer images from regular flat printing plates. But we also make special rotary pads that work with rotary cliché drums. ... Unlike regular flat pad printing, rotary pad printing uses a spinning silicone roller to pick up ink from an engraved plate and apply it directly onto a moving, round object. This method is great for smooth and accurate printing on items like syringes or bottle caps, especially when printing needs to be done quickly.

Special printing pads for Tagless neck labels are made from high-quality silicone rubber, ensuring excellent ink absorption and smooth release for precise image transfer. ...